|

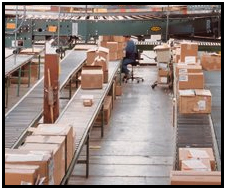

This retail distributor knows that one of the best ways to stay ahead in this fast-paced industry is to streamline your distribution system. With that in mind, they created a logistics and operations unit with a mission to drastically cut both costs and processing time in merchandise distribution for their retail locations. The mission was successfully carried out thanks in large part to a conveyor system from Hytrol. The 520,000 square-foot facility replenishes stores located in a five-state region in the Northwest.

Setting The Objectives

Virtually all (98%) of the merchandise moves through the facility with no manual handling, a big factor in the high productivity and throughput levels now being achieved. That wasn't always the case, though. Prior to installation of the new conveyor equipment, about 20 percent of the cartons could not be placed on the existing conveyors because of size constraints. These larger boxes had to be handled and moved throughout the facility manually, adding time and cost to the D.C.'s operation. Virtually all (98%) of the merchandise moves through the facility with no manual handling, a big factor in the high productivity and throughput levels now being achieved. That wasn't always the case, though. Prior to installation of the new conveyor equipment, about 20 percent of the cartons could not be placed on the existing conveyors because of size constraints. These larger boxes had to be handled and moved throughout the facility manually, adding time and cost to the D.C.'s operation.

The company wanted a new system that addressed the carton size problem as well as realized the following objectives:

- Achievment of zero-pressure accumulation with maximum density.

- Lowered maintenance costs.

- Reduced noise levels throughout the distribution center.

All of these objectives—and more—were acheived by working closely with a system integrator and Hytrol Integration Partner throughout the equipment selection and installation process. The new conveyor units included a zero-pressure horizontal live roller with the exclusive EZLogic® feature (190-ABEZ); a roller bed belt conveyor (190-RB); and a horizontal sawtooth merge (190-LR).

Multiple Benefits Realized

The distribution center is designed as a cross-dock operation emphasizing flow, not storage. Cartons are unloaded from trailers and containers and placed on incline belts that carry them up to four ceiling-supported zero-pressure conveyors. They then travel down the zero-pressure lines toward a high-speed sawtooth merge, which helps keep the merchandise from backing up in receiving. A takeaway conveyor transports the cartons to the shipping side of the facility where they are sorted by store location. After sortation, high-speed pushers send the merchandise onto zero-pressure lines, which discharge onto a chute and then onto extendable belt conveyors. These extendable units are brought right to the trailer for rapid loading to each store location. The distribution center is designed as a cross-dock operation emphasizing flow, not storage. Cartons are unloaded from trailers and containers and placed on incline belts that carry them up to four ceiling-supported zero-pressure conveyors. They then travel down the zero-pressure lines toward a high-speed sawtooth merge, which helps keep the merchandise from backing up in receiving. A takeaway conveyor transports the cartons to the shipping side of the facility where they are sorted by store location. After sortation, high-speed pushers send the merchandise onto zero-pressure lines, which discharge onto a chute and then onto extendable belt conveyors. These extendable units are brought right to the trailer for rapid loading to each store location.

From receiving to shipping, the flow is fast, simple, and direct-all attributes that support the company and operations mission. The system has also been highly reliable and trouble free, a positive factor in reducing maintenance costs.

"We particularly appreciate the system's EZ Logic features," adds Maintenance & Engineering manager. "The photoeye keep big cartons from damaging the smaller ones. And we're able to do singulation release of the boxes. I would recommend this system to anyone."

|