|

This corporation specializes in beef processing for the consumer market and provides various grades of boxed beef products to wholesale/retail distributors and high-volume users. The facility has operated since the mid-1980s in a fully automated warehouse.

Goals For The New System

The company started off using pallet-based "ship to order" automated systems because many customers no longer wanted beef boxes being lumped into trucks, forcing a labor-intensive process on receipt. More often, pallet orders needed to be delivered; a significant change for the plant distribution operation.

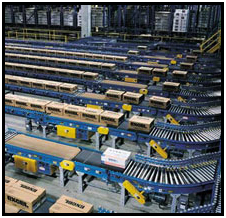

The mechanized distribution system needed to be converted from a case loading direct-to-truck operation to a pallet-shipping process without interrupting its daily business. To meet the new business model, new AS/RS storage buffers and associated box sortation, accumulation and transport would need to be managed, along with high-speed palletizing and stretch wrapping.

The solution was delivered by a Hytrol Integration Partner. They retrofitted the old order delivery system and developed business-specific software to continue high volume handling and shipping postponement strategies. The custom software visibility allows the production and shipping managers to make the right decisions in filling orders and setting demands on the production floor.

Today, the "new" order delivery system ships over 90 trucks a day in two shifts with orders ranging from 1 SKU per truck to completely mixed products, often all on pallets. Some orders only have hours or minutes to be satisfied from the time the right product arrives from the box sealers.

|