|

The time to market for gaming systems is critical and their release date is often a highly publicized event. If everything goes right the demand will surge. Your distribution center needs to be ready.

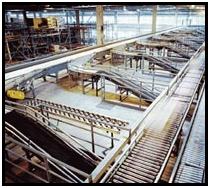

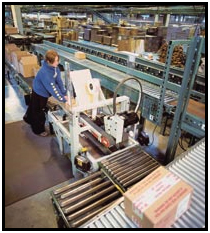

With an estimated 40% of American households owning a video gaming system, this manufacturer of video game hardware and software has achieved remarkable market penetration. With a market of that size and magnitude the supporting distribution center has to keep up with orders quickly and accurately. This modern 380,00 square foot facility processes more than 20,00 orders a day for customers including retail store and a growing number of consumers who order their video games and components online.

Keeping Pace With A New Sortation System

Disadvantages of the old system:

- The old sorter could not handle packages smaller than 8"x12". Consequently, there was a lot of "air" in many of the small orders. This, in turn, resulted in poor cube utilization of the trucks and airfreight containers, which translated to unnecessarily high transporation costs.

- Certain packages that were prone to rotate during the order-flow process had a no-read rate of 10%.

- On top of all this, the old operation was noisy.

The new system addresses all of these issues — and more. It is considerably  more efficient and productive than its predecessor and is notable in a number of respects. more efficient and productive than its predecessor and is notable in a number of respects.

- Effectively streamlines product flow throughout the facility with a series of merges

- Incorporates advanced gapping technology and a sortation system that can handle more than 145 packages a minute

- Integrates a mix of proven Hytrol conveyor equipment, including the unique EZ Logic accumulation system

|