How  's ProSort MRT Benefits You 's ProSort MRT Benefits You

- Right angle transfers save you up to 75% of the floor length required for sortation equipment.

- Two sided transfer mechanisms save money by reducing hardware & allowing the unit to be a sort or induction point.

- High sort rates make the MRT perfect for use within picking modules and order consolidation stations.

- Close transfer locations make working within the constraints of your facility much easier.

- Flexible sort locations provide you the ability to change your operation as often as you need.

- HyPower distributed cable system slashes field wiring expenses and simplifies changing locations.

Applications Applications

- Shipping operations where dynamic lane assignments by carriers, route or customer are critical to your efficiency.

- Internal routing processes where kitting, order consolidation or zone routing streamline your order flow.

- Manufacturing facilities where product is conveyed to a variety of sequential operations during the build process.

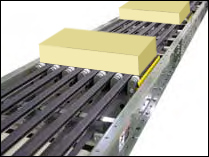

The ProSort MRT is Seamless 90° Sortation

The Medium Roller Transfer (MRT) Conveyor makes use of multiple narrow belts to transport items and is equipped with right-angle pop-up rollers that pop up between the belts to transfer items off the unit.

The MRT is meant to handle and transfer medium-sized items. Minimum package size is 8 x 6 inches wide, maximum package length is 28 inches with a maximum unit package weight of 75 lbs.

The MRT is designed for 2-sided transfer of items. Product can be transferred off either side of the conveyor to other right angle conveyors, workstations, packing operations, ticketing stations, shipping departments, or other similar operations. The unit is a capable of handling high sort rates and comes equipped with the HyPower Distributed Cabling System.

Download the ProSort MRT Catalog Sheet Download the ProSort MRT Catalog Sheet

|